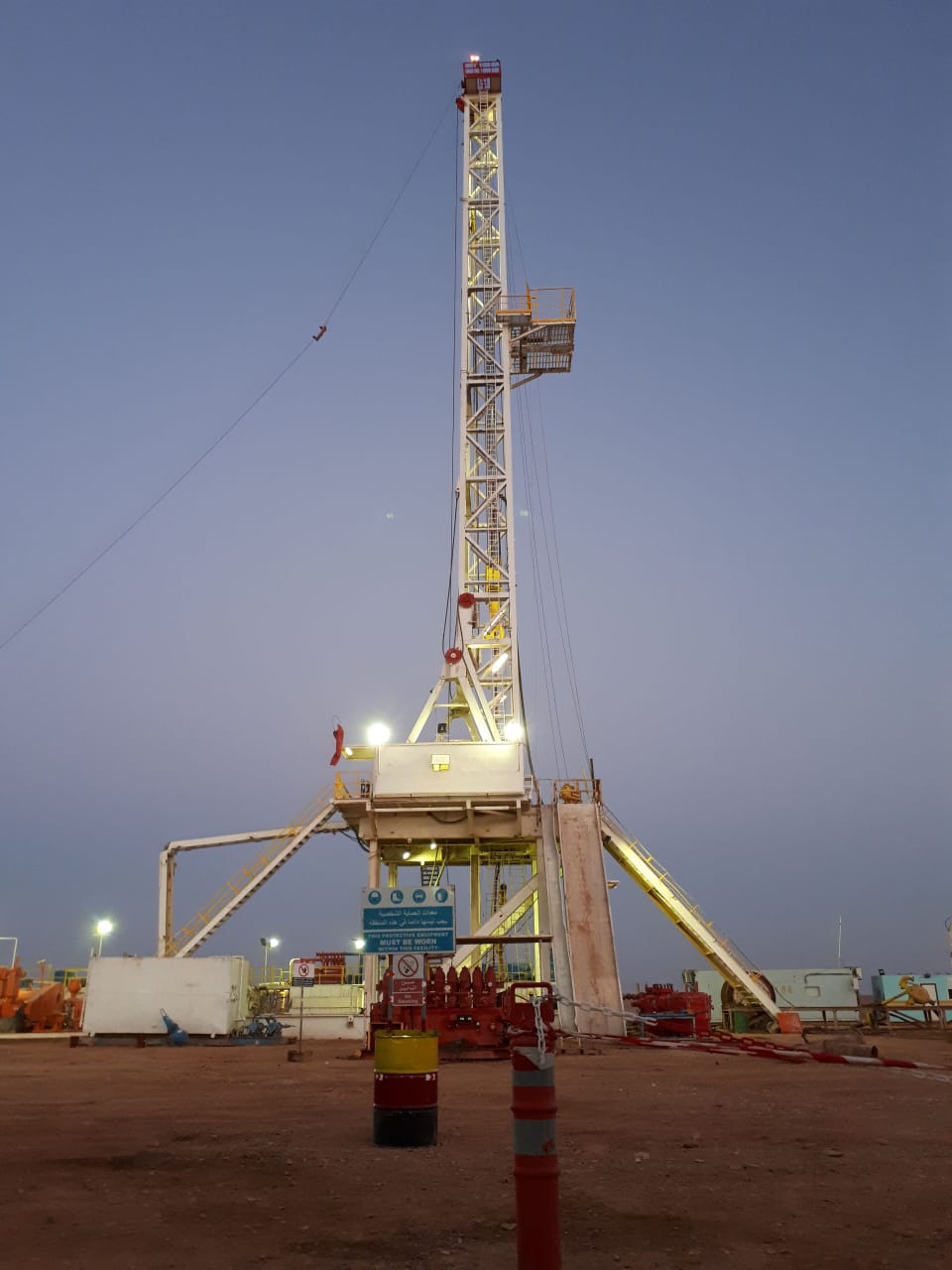

Amra

& Jerash Rigs: Body Repair & Structural Validation

Client:

National Petroleum Company (NPC)

For

the Amra and Jerash Rigs, Synergy Quality Inspection Services provided critical

oversight during a major body repair and maintenance cycle. In the

high-pressure environment of the National Petroleum Company’s operations,

ensuring structural reliability is the first line of defense against

operational failure.

The

Technical Edge

Our

team executed a rigorous dual-method inspection protocol to certify the quality

of the repairs:

*

Visual Testing (VT): A comprehensive surface audit to identify immediate

structural concerns, corrosion, and weld alignment.

*

Magnetic Particle Testing (MT): Precise detection of surface and near-surface

discontinuities in the rig’s ferromagnetic components, ensuring that even

invisible stress cracks were addressed.

The

Result

By

integrating Synergy’s NDT (Non-Destructive Testing) expertise directly into the

maintenance workflow, we ensured that the Amra and Jerash rigs returned to the

field with zero defects. Our intervention provided the NPC with the documented

assurance that their assets meet stringent safety standards and are prepared

for continued high-demand performance.