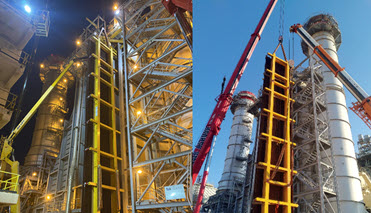

Boiler

Life Assessment & Integrity Study: Units 1 & 2

Client:

AES Jordan PSC

For

Units 1 & 2 at the AES Jordan power station, Synergy Quality Inspection

Services was commissioned to perform a comprehensive Remaining Life Assessment

(RLA). In the power generation industry, boilers are subjected to extreme

thermal cycling and high-pressure environments that inevitably lead to material

fatigue. Our mission was to provide a data-driven "health check" to

ensure these units could continue to meet national energy demands without the

risk of catastrophic failure or unscheduled outages.

The

Technical Execution: A Multi-Layered Approach

To

build a complete profile of the boilers' structural health, our team deployed a

sophisticated inspection regimen designed to catch both surface-level and

internal degradation:

*

Precision Corrosion Mapping (UTT): Rather than taking random samples, we

performed systematic Ultrasonic Thickness Testing across the boiler’s pressure

parts. This allowed us to generate a detailed "topography" of the

metal, identifying specific zones of thinning caused by fly-ash erosion and

high-temperature oxidation. This data is critical for calculating the precise

remaining wall life of the tubes.

*

Magnetic Particle Testing (MT): We focused our MT efforts on high-stress weld

joints and headers. By utilizing electromagnetic yokes, we were able to detect

microscopic thermal fatigue cracks that are invisible to the eye but can

propagate into major leaks under the intense pressure of power operations.

*

Expert Visual Testing (VT): Our certified inspectors conducted a full-scale

internal and external audit, looking for signs of overheating, structural

sagging, and insulation breakdown.

The

Strategic Impact

The

result of this study was more than just a list of findings; it was a strategic

asset for AES Jordan. By providing a clear "Corrosion Map" and

integrity report, Synergy empowered the client to move from a reactive

maintenance model to a proactive, predictive one.

Our

findings allowed for the pinpointing of exactly which components required

immediate replacement and which could safely remain in service until the next

scheduled outage. This precision reduced unnecessary maintenance costs while

significantly bolstering the plant's operational safety and reliability.

Ultimately, Synergy’s assessment provided the technical confidence needed to

continue high-output energy production with a minimized risk profile.